Transportation and relocation

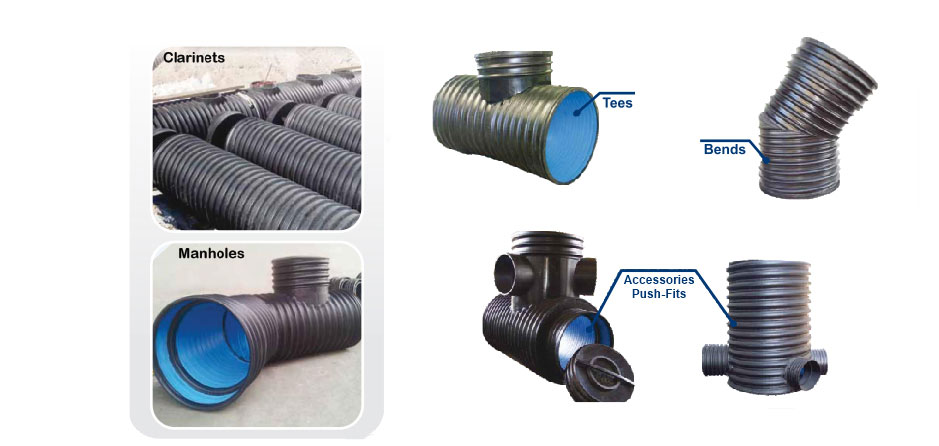

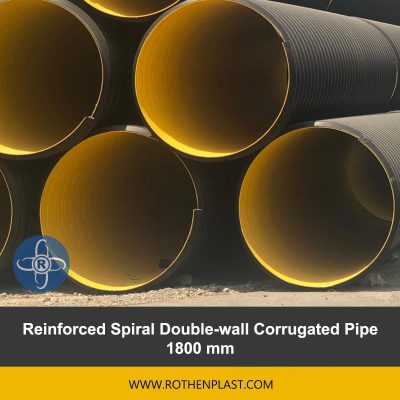

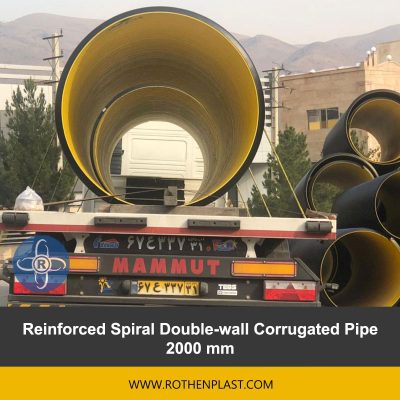

The reinforced spiral corrugated pipes must be handled according to the requirements generally observed with traditional pipes. Rothen Plast pipes can be stacked up without any problem thanks to their light weight and high ring stiffness. Loading, transporting, unloading, and all related operations must be carried out with great care, by using means and devices appropriate to the type of pipes, and taking all the safety measures in order to avoid breakage, cracks, and damages. The pipes should be stored in a flat and safe area. The first row of the pipes that is placed on the ground must be arranged to avoid possible damages to the outer surface, such as bending and deformation.

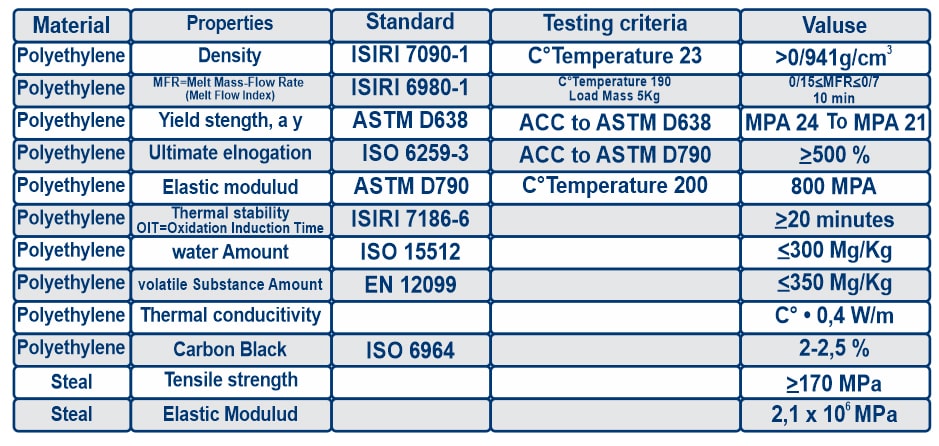

Stacked pipes must be protected with appropriate wedges in order to prevent sudden falls.

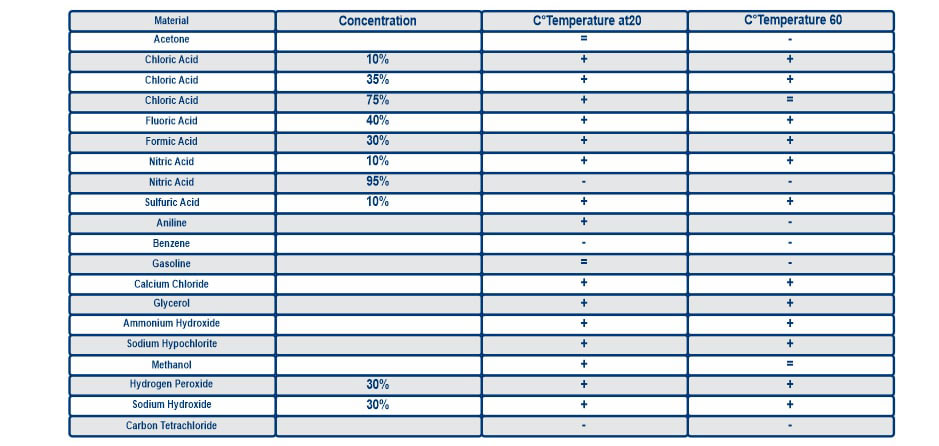

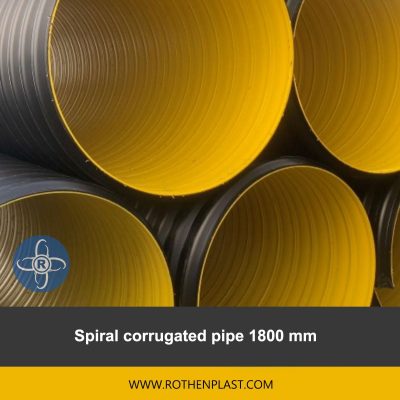

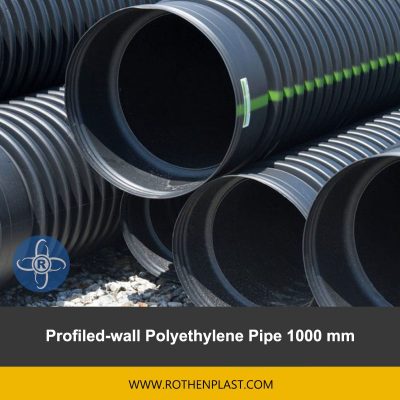

The spiral double-wall corrugated pipes, have a high ring stiffness due to their design. The HDPE-PP raw materials are more resistant against chemicals compared to all the plastic materials. Therefore, Rothen Plast offers corrugated pipe as the best choice in terms of resistant against chemicals. The studies show that corrosion in metal and concrete sewer pipes, are more than pipes made of polymer. Corrugated and spiral pipes are resistant against acids and bases. These pipes are not conductive and due to their weight, they are suitable for telescopic transmission (pipe in pipe) and also, they are optimized and convenient in terms of cost and installation time. Therefore, corrugated pipes, unlike concrete and metal pipes , do not need heavy equipment and high expenses to get installed. Corrugated pipes, compared to concrete and metal pipes are about 30 times lighter and they are recommended to be used in sewage systems as the best

option for longevity and cost-effectiveness

A : Base fill

base of the ditch should be compact sand for AH should be minimum 150 mm for easy installation.

B : side fill

After the installation of the pipes by centering over the base fills are prepared out of compact ground cleared of keen and sharp particles

C : Upper fill

after completing the side fill the ditch is filled with the soil closed

CH should be minimum 500 mm extracted from the channel and closed CH should be minimum 500 mm.

SPR pipes

LARGE DIAMETER TRENCHLESS PIPE RENEWAL

The SPR trench-less method is the best choice for pipeline renewal process and rehabilitation of large diameter pipelines up to 5000mm. SPR utilizes steel reinforced interlocking PVC profile strips grouted in place with a high compressive strengths grout. The installation equipment can be used through standard access points with no need with no need for excavation. The Japanese SPR technology can also be installed in vertical applications such as water wells, access shafts, and other large diameter structures. The SPR process is unique in providing a customized structural solution to eroding pipelines. This method can also be used to fix hydraulic anomalies as well as restoring the slope of the original pipe by appropriate engineering.

SPR pipes have been examined in accordance with Industry standards for spiral and PVC Profiled-wall pipes ASTM F 1697 and ASTM F 1741. Furthermore, the PVC profile of SPR contains Manning’s n of 0.01

INSTALLATION PROCESS – MINIMAL IMPACT ON THE ENVIRONMENT

The installation process of SPR pipe can be divided in the following steps:

- Inspection and cleaning of host pipe 2. Wound lining

- Installation of bracing system 4. Grouting

Inspection

Prior to the SPR wound lining, the host pipe gets inspected via camera and all incrustation and debris should be removed by hydraulic jet cleaning.

SPR wound lining

The SPR profile gets fed through the manhole into the winding machine placed in the existing pipe. Due to the forward motion, the winding machine moves to the next access chamber. For longer rehabilitation sections, the profile gets cut off at the intermediate shaft and the winding machine should be installed behind it to continue the winding process.

Bracing system

After the winding process is completed, the bracing system will be installed. The bracing material gets lowered through standard manhole openings. In the next step, the bracing system gets set up to provide structural support during the grouting process and positions the SPR profile in the existing pipe according to engineering specifications.

Grouting

The grouting process is injection of grouting material into annular space between existing pipe and wounded PVC profile. The pipe will be ready to use after this stage.

Benefits of SPR at a glance

- Rehabilitation of large diameter pipes (800-5000 mm)

- Rehabilitation of circular, non-circular and custom shapes

- Truly trench-less – requires only standard manhole entry

- Designed for installation in live flow conditions

- can be installed in curves and bends

- Improved flow with smooth PVC material (Manning’s n of 0.01)

- Environmental – friendly installation and application

- Over 400 km successfully installed world-wide

SPR PE

THE HDPE REINFORCED PIPE FOR GRAVITATIONAL PIPELINE

The SPR PE pipe is a great choice to restore and rehabilitate the hydraulic efficiency, reliability, and integrity of old sewage systems, drainage systems, and culverts. The fully encapsulated steel reinforcement, is designed to provide a liner of optimum stiffness. The SPR PE pipes can structurally rehabilitate brick, concrete, glass reinforced plastic, corrugated metal sanitary sewer and storm-water pipelines with diameters from 900mm to 3000mm. The plastic profile that forms the pipe is provided in a range of sizes. The profile is reinforced with steel that is completely encapsulated within the HDPE material. The steel reinforcement is selected to provide a pipe with sufficient stiffness to meet the requirements of the project.

Project experiences

SPR PE has been used to rehabilitate sewage system, storm-water lines, and culverts around the world . It has been proven capable of providing a structural pipeline for severely deteriorated pipelines. Also, it is capable of getting installed under difficult site conditions with minimal community disruption.

Easy mechanical installation

At first, the deteriorated pipeline gets cleared of debris and obstructions, cleaned and inspected. Then, the diameter gets measured and approved. After this stage, the winding machine gets lowered to the base of the access chamber through the standard manhole openings, and the reinforced HDPE profile gets fed into the machine form an above ground spool. The winding machine then starts the wound lining process and forms the reinforced HDPE into a new pipe. The process continue until the liner wounded by the winding machine reaches the end of the pipeline. The end of the liner at both access chambers gets sealed and rendered.

The annulus between the fixed diameter liner and the host pipe can be filled with grout immediately after the winding is completed.

Proven pipe material

- Made from similar grade of HDPE as new sewage and drainage pipes

- Cell Classification of 33540C(or E)in accordance with ASTM D 3350

- Profile sealing is achieved by extrusion welding to produce a continuous joint-less HDPE liner

- Consistent material properties. The strength of the pipe does not rely upon the grout.

Design

Numerous industry specifications provide design methods applicable to SPR PE, including :

- ASTM F 1741: “ Standard method for installation of winding machine is available. This standard has been modified for SPR PE (HDPE) pipe.

The best solution in whole world

The modern urban life would be utterly impossible without underground infrastructure. Furthermore, it is becoming apparent that underground infrastructure system in the whole world, is substantially deteriorating as a result of age and increase in traffic loads. Additionally, the demand for sustainable and environmentally-friendly urban development is rising and this can pose a great challenge to local authorities. SEKISUI SPR, offers the best solution to these demands. The Trenchless technology has made the renovating the underground infrastructure a lot more simple and affordable, by rehabilitating and improving the existing system. This method, eliminates the protracted construction and modification of the cityscape. It also makes the expand and maintenance of the existing infrastructure system possible without excavation. The Trenchless technology, guarantees a much quicker, cost-effective, and environmentally-friendly solution, instead of replacing the system. SEKISUI SPR, employs the world’s best technical and operational infrastructure specialists, therefore, they can offer the best solution for all requirements from planning to construction. SEKISUI SPR operates in three divisions in order to answer to the needs of the customers; Sales and support, Trenchless Infrastructure Solutions, and construction. This provides a global interchange of experience for all experts to devise the optimum infrastructure solution for the projects. SEKISUI SPR brings together the competence of the SEKISUI Chemical Corporation (Osake). This is already represented in over 40 countries around the world.